Table of Contents

- Introduction: Beyond Function – The Rise of Aesthetic Yarns in the Modern Supply Chain. What is Fashion Yarn?

- Defining “Fashion Yarn”: The Intersection of Aesthetics, Material Innovation, and Market Demand

- Core Categories of Fashion Yarns: A Detailed Taxonomy

- 3.1. Novelty & Fancy Yarns (Chenille, Bouclé, Slub, Flammé)

- 3.2. Metallic & Lurex Yarns

- 3.3. Tape & Ribbon Yarns

- 3.4. Specialty Blends: Sustainable, Recycled, and Bio-Based

- 3.5. High-Tech Functional Yarns with Aesthetic Appeal

- Production Techniques: How Fashion Yarns are Engineered

- 4.1. Spinning Variations (Siro, Core, Wrap)

- 4.2. Printing, Dyeing, and Space-Dyeing Techniques

- 4.3. Laminating, Coating, and Embossing

- 4.4. Post-Processing and Finishing

- Technical Specifications and Performance Considerations

- 5.1. Structural Integrity vs. Aesthetic Effect

- 5.2. Compatibility with Weaving, Knitting, and Tufting Machinery

- 5.3. Durability, Pilling, and Care Requirements

- Application-Specific Analysis and Selection Guide

- 6.1. Apparel (Knitwear, Woven Accents, Trim)

- 6.2. Home Furnishings & Upholstery (Decorative Cushions, Throws)

- 6.3. Footwear and Accessories

- 6.4. Technical Textiles with Fashion Crossover

- Market Trends Analysis: Data-Driven Insights

- Procurement and Sourcing Strategies for Fashion Yarns

- 8.1. Evaluating Supplier Capability and Innovation Pipeline

- 8.2. Minimum Order Quantities (MOQs) and Lead Times

- 8.3. Cost-Benefit Analysis of Fashion vs. Standard Yarns

- Sustainability and Ethical Dimensions in Fashion Yarn Production

- Future Outlook: Digital Integration and Smart Fashion Yarns

- Conclusion: Strategic Implementation for Product Differentiation and Value Addition

- Frequently Asked Questions (FAQ)

1. Introduction: Beyond Function – The Rise of Aesthetic Yarns in the Modern Supply Chain

For procurement managers and product developers across industries, the definition of yarn has evolved from a purely functional component to a primary vehicle for design expression and market differentiation. Fashion yarn represents this paradigm shift. It is no longer sufficient to source yarns based solely on count, strength, or fiber content. Today’s competitive landscape demands an understanding of yarns that deliver texture, visual dynamism, tactile surprise, and storytelling potential. This guide provides a comprehensive technical and commercial exploration of fashion yarns, empowering you to leverage these innovative materials to create standout products in apparel, home textiles, and beyond.

2. Defining “Fashion Yarn”: The Intersection of Aesthetics, Material Innovation, and Market Demand

A fashion yarn is primarily characterized by its intentional deviation from standard, uniform appearance. Its value proposition lies in its ability to create immediate visual and textural impact in the final product. Key defining elements include:

- Aesthetic Dominance: Visual or tactile effect is the primary raison d’être.

- Innovative Construction: Often involves complex spinning, plying, or post-processing.

- Seasonal Relevance: Strongly tied to color and texture trends from fashion forecasting.

- Value Addition: Commands a price premium over standard yarns, justified by enhanced design appeal.

3. Core Categories of Fashion Yarns: A Detailed Taxonomy

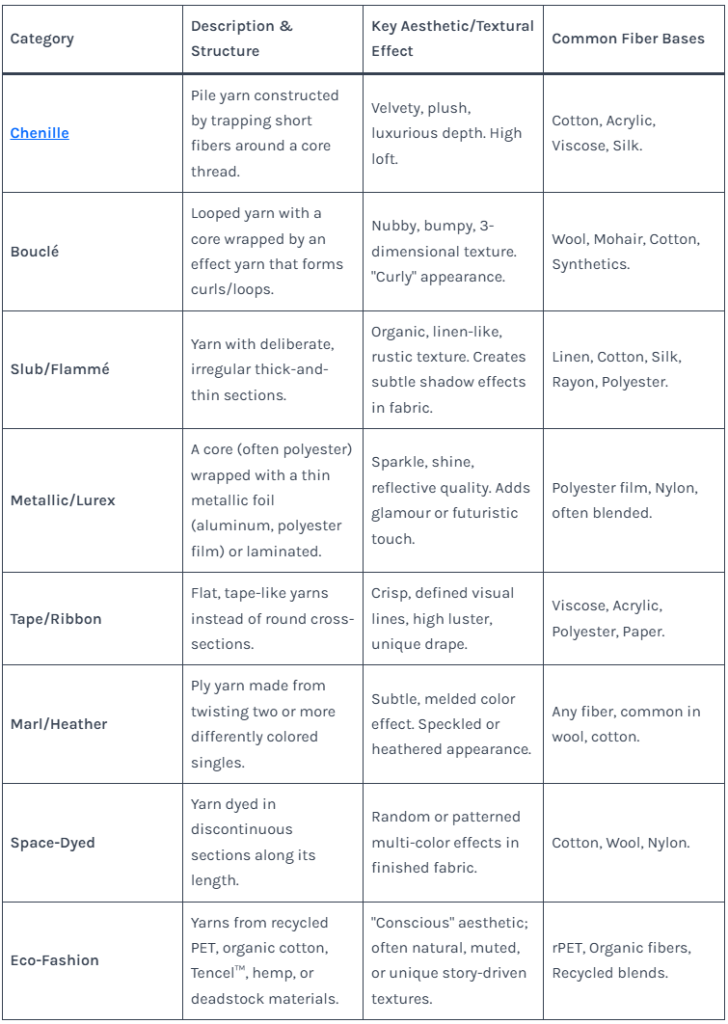

Table 1: Major Fashion Yarn Categories and Characteristics

4. Production Techniques: How Fashion Yarns are Engineered

4.1. Spinning Variations:

- Core Spinning: Essential for stability in novelty yarns (e.g., a strong filament core for chenille).

- Wrap Spinning: A decorative yarn is spirally wrapped around a core, creating smooth or textured effects.

- Hollow Spindle & Fancy Twisting: Specialized machines create loops, snarls, and gimps.

4.2. Dyeing Techniques:

- Space Dyeing: Multiple colors applied to specific sections of yarn skein or package.

- Printing/Yarn Painting: Precise color application for highly patterned effects.

- Ombré/Gradient Dyeing: Color transitions smoothly along the yarn length.

4.3. Laminating and Coating:

Metallic yarns are created by laminating polyester film with aluminum and slitting it into fine ribbons, often then wound around a core. Yarns can also be coated for iridescent or color-change effects.

5. Technical Specifications and Performance Considerations

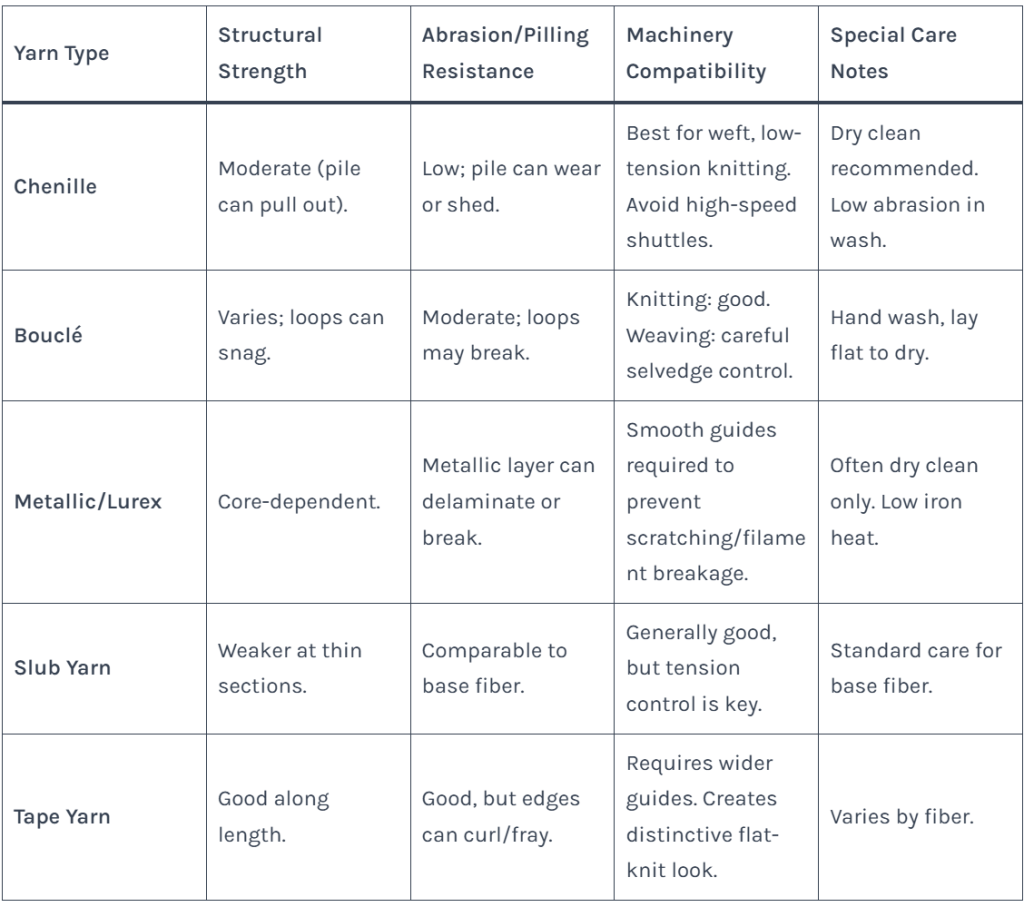

Table 2: Performance Considerations for Select Fashion Yarns

6. Application-Specific Analysis and Selection Guide

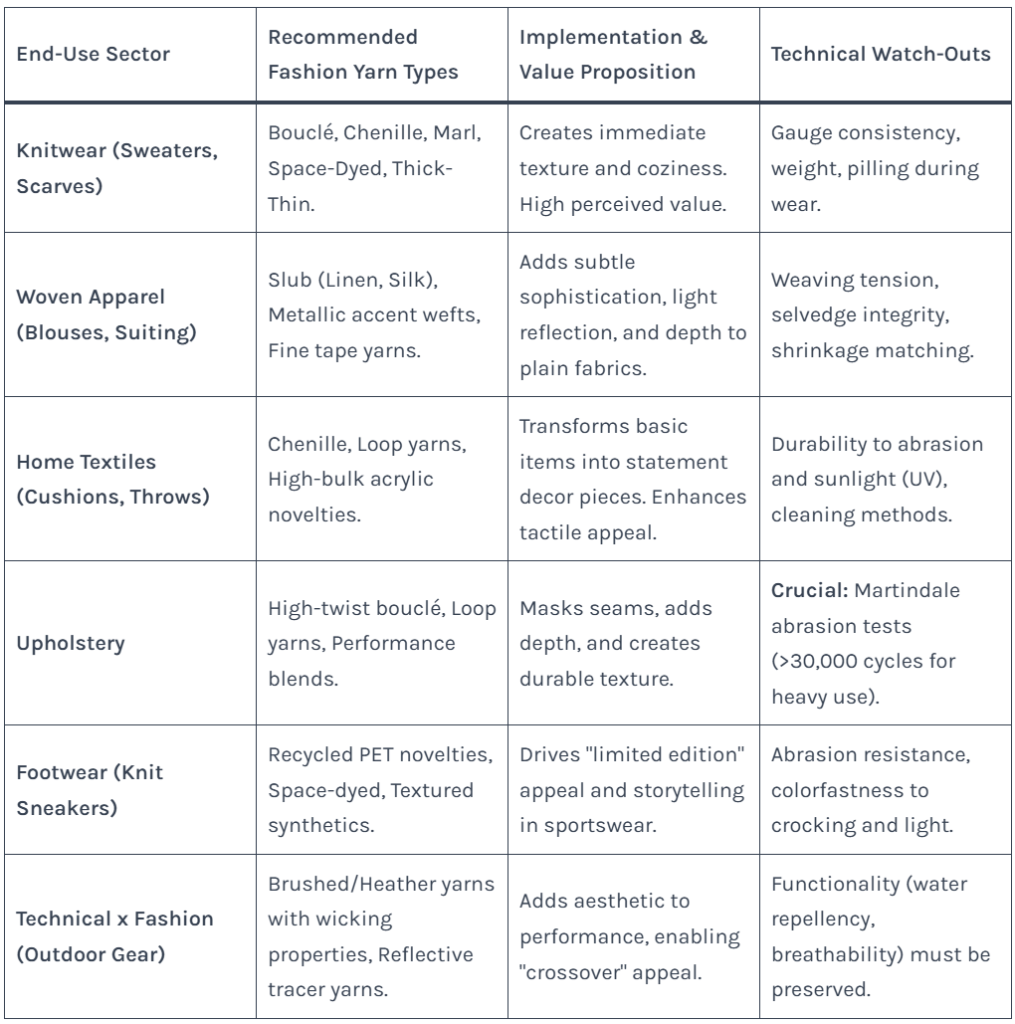

Table 3: Strategic Application of Fashion Yarns

7. Market Trends Analysis: Data-Driven Insights

- Demand Drivers: Rise of “experience” over product, social media visual culture, growth of home decor DIY.

- Growth Segments: Sustainable fashion yarns (CAGR >8%), metallic yarns in athleisure, ultra-soft chenille for loungewear.

- Regional Preferences: Europe: emphasis on natural fibers and subtle textures. North America: bold colors and high-contrast effects. Asia: innovation in synthetic novelties and metallic blends.

8. Procurement and Sourcing Strategies for Fashion Yarns

- Supplier Evaluation: Assess sample-making speed, R&D capability, and trend forecasting alignment.

- MOQ Realities: Fashion yarn MOQs are typically higher than standard yarns (500kg – 2000kg) due to complex setup. Deadstock or recycled yarns may have lower, inconsistent MOQs.

- Cost Analysis: Factor in potential lower machine efficiency, higher waste, and the premium for design. The ROI comes through higher final product selling price and sell-through rates.

9. Sustainability and Ethical Dimensions

The fashion yarn sector faces scrutiny. Key initiatives include:

- Recycled Content: rPET, recycled cotton, and regenerated nylon (e.g., from fishing nets).

- Traceable Natural Fibers: Organic wool, responsibly sourced mohair.

- Low-Impact Dyeing: Water-saving space-dye techniques, OEKO-TEX certified dyes.

- Circular Design: Creating yarns designed for disassembly or recycling.

10. Future Outlook: Digital Integration and Smart Fashion Yarns

- Digital Yarn Printing: Allows for infinite customization with minimal waste.

- Smart Yarns: Integration of conductive fibers for illuminated textiles (LED) or interactive clothing.

- 3D Yarn Structures: Engineered yarns that create pre-determined 3D textures when knitted or woven.

- AI-Driven Trend Matching: Using AI to analyze trend data and recommend yarn developments.

11. Conclusion: Strategic Implementation for Product Differentiation and Value Addition

Fashion yarns are not merely decorative extras; they are strategic tools for product development and market positioning. For the procurement professional, success lies in moving from a cost-centric to a value-innovation-centric mindset. This involves:

- Early Integration: Involving yarn selection at the conceptual design phase.

- Technical Partnership: Working closely with spinners to develop proprietary effects.

- Holistic Costing: Evaluating the total value chain impact, from manufacturing efficiency to retail margin.

By mastering the categories, production nuances, and application strategies outlined in this guide, you can systematically harness the power of fashion yarns to reduce commoditization, enhance brand identity, and capture higher-margin market segments.

12. Frequently Asked Questions (FAQ)

Q1: What is the main difference between a fashion yarn and a standard yarn?

A: The primary difference is intent. A standard yarn is engineered for consistency, strength, and processability. A fashion yarn is engineered for deliberate visual or textural irregularity and aesthetic impact. It prioritizes design effect over uniformity.

Q2: Are fashion yarns less durable than regular yarns?

A: They can be, but it’s not a rule. Durability depends on the construction and base fiber. A bouclé made from fine mohair may snag easily, while a slub linen yarn is as durable as standard linen. The key is to match the yarn’s performance profile to the end-use. Technical specifications for abrasion and pilling are critical for evaluation.

Q3: Can fashion yarns be used in industrial tufting for carpets?

A: Absolutely. This is a major application. Chenille, loop, and high-low pile yarns are extensively used in residential and hospitality carpets to create intricate patterns and luxurious textures. They require specialized tufting machine configurations.

Q4: How do I calculate the required quantity of a space-dyed or irregular yarn for a production run?

A: You must account for higher waste and inconsistency. Standard calculations based on weight or length may fall short. The best practice is to run a production pilot with the exact yarn to determine the real-world yield and create a unique shrinkage and waste factor for that specific yarn lot.

Q5: What are “deadstock” or “upcycled” fashion yarns?

A: These are yarns created from post-industrial waste—leftover yarns from large mills or unsold inventory. They are often unique, small-batch, and promote sustainability. Consistency and repeatability are challenges, but they offer exclusive storytelling appeal for limited collections.

Q6: How does using a metallic yarn affect the manufacturing process?

A: It introduces several considerations: 1) Machine Guides: Require ceramic or polished surfaces to prevent scratching and breaking the metallic layer. 2) Tension: Must be carefully controlled and even. 3) Cleaning: Metallic particles can accumulate in machines. 4) Knotting/Splicing: Requires special techniques to avoid visible joins.

Q7: Are there flammability concerns with certain fashion yarns?

A: Yes. Metallic yarns can be conductive and pose a risk if not properly insulated. Chenille and brushed yarns may have higher surface area and could be more flammable if made from certain synthetics. For children’s sleepwear, upholstery, or aviation interiors, strict flammability standards (e.g., 16 CFR Part 1610, FMVSS 302) must be verified.

Q8: What is the lead time for developing a custom fashion yarn?

A: Lead times are significantly longer than for standard yarns. For a custom development (new color, blend, or effect), expect 3 to 6 months from concept to delivery of production quantities, depending on complexity and spinner capacity. Always include this in seasonal development calendars.

Q9: Can I blend a fashion yarn with a standard yarn?

A: Yes, and this is a common strategy. Blending a fashion yarn in the weft with a standard yarn in the warp reduces cost, adds stability, and creates more subtle effects. It requires testing for shrinkage, strength, and aesthetic compatibility.

Q10: How important is colorfastness in fashion yarns?

A: Critically important, especially for space-dyed or marled yarns. Poor colorfastness can lead to bleeding, frosting, or unexpected color shifts in the final product. Demand test reports for wash fastness, light fastness, and crocking (rubbing) specific to the yarn construction, not just the base fiber.

Leave a Reply